Introduction

The Singer Brilliance 6180 is a sewing machine notable for its user-friendly features. Tension requirements vary based on fabric and machine settings, and users often run into issues regarding thread tension for this particular machine. Maintaining correct thread tension is essential to achieving high-quality stitches and when thread tension is impaired, whether too tight or too loose, this can lead to poor stitching, fabric damage, and needle breakage.

In this guide, we'll cover how to restore optimal thread tension, replace the needle, and provide preventative maintenance measures to keep your machine running smoothly and producing prime stitches!

Parts

-

-

To test the thread tension, take a scrap piece of fabric and sew a short line.

-

Adjust thread tension as needed and retest until it is correct.

-

-

-

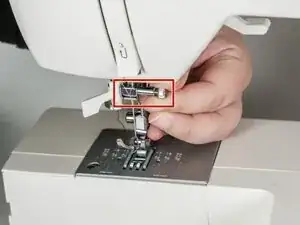

To replace a needle, begin by unscrewing the screw located to the right of the needle.

-

Rotate the screw away from you to loosen the screw.

-

-

-

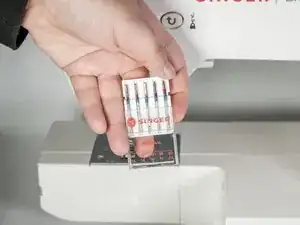

Remove the needle. Replace the needle with a fresh needle.

-

Rotate the screw away from you to tighten the screw.

-

-

-

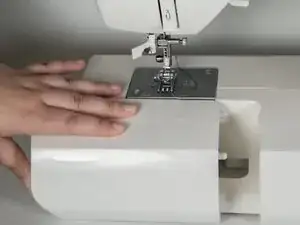

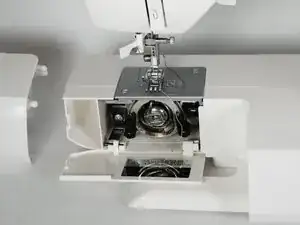

To check the bobbin, remove the front section of the sewing machine by firmly sliding the section to the left.

-

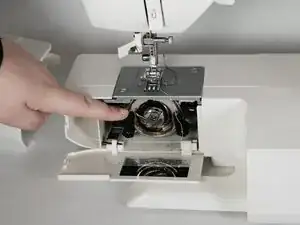

Open the hinge door towards you to reveal the bobbin.

-

Check to see if the bobbin is firmly in place. If the bobbin is loose, shift the bobbin to fit firmly in place.

-